I’ve been printing and building the 3DLabPrint A-10. They provide a link to purchase landing gear retracts on AliExpress, however the link goes to a set which does not fit the 3D printed sockets. Fortunately, it was not a difficult fix. All I used was a candle and a screwdriver.

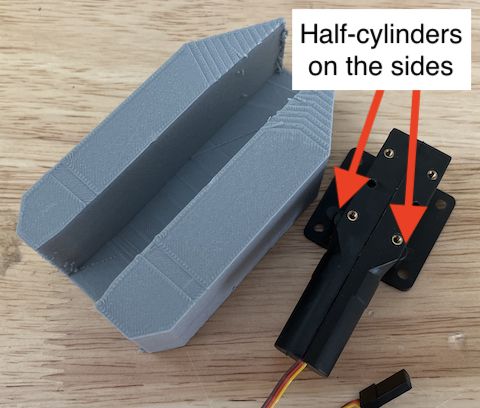

I thought about taking a rotary tool to it and carving out spots for the half-cylinders. However I decided it was better to use heat to make an indent in the plastic instead. I found a screwdriver that was roughly the same diameter as the half-cylinders.

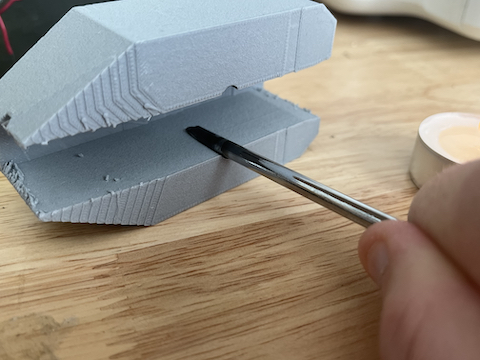

I heated the tip of a screwdriver over a candle then used it to create a groove for the half-cylinders in the retract socket. Each groove took a few iterations of heating and pressing into the plastic before the groove was deep enough.

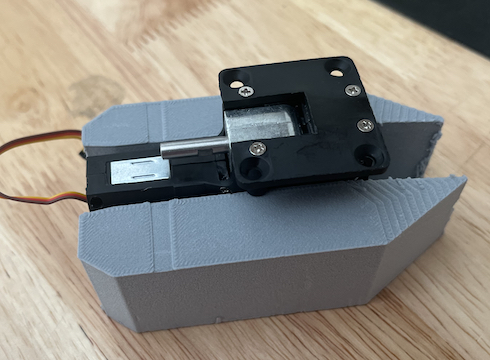

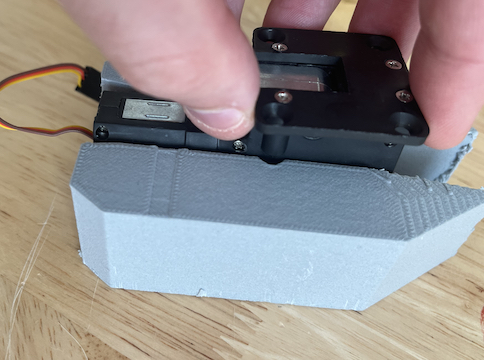

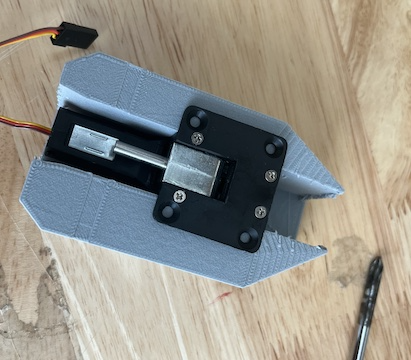

With the grooves in place, the retracts fit perfectly into the socket.

I think that the hot screwdriver was the way to go. Drilling out the groove would be messier and also would remove the wall of the 3d print, reducing the integrity of the part. A soldering iron would probably also work well.